In the rapidly evolving landscape of manufacturing, the concept of the “connected factory” is revolutionizing how work is done. This shift isn’t just about technology—it’s about transforming the workforce to be more engaged, efficient, and safer than ever before. The rise of the connected factory worker is central to this transformation, driven by advancements in Industrial IoT (IIoT), wearable technology, and real-time data analytics.

In this article, we will explore the key elements of the connected factory, the technologies enabling this shift, and the profound impact it’s having on the manufacturing workforce.

The Rise of the Connected Factory Worker

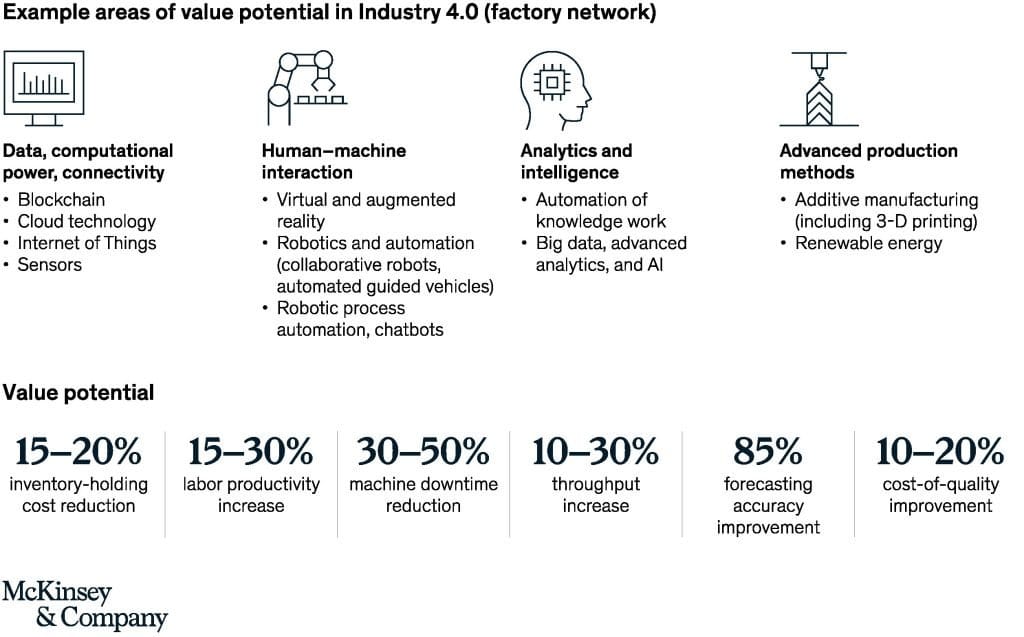

The adoption of Industry 4.0 technologies can lead to an increase of 15% to 30% in labor productivity

As manufacturing enters the era of Industry 4.0, the role of the factory worker is being redefined. The connected factory worker is not just a participant in the production process but a crucial link in a highly integrated, smart manufacturing environment. This transformation is fueled by the adoption of Industrial IoT in manufacturing, which connects workers, machines, and systems in real time, enabling seamless communication and coordination.

According to a study by McKinsey, the adoption of Industry 4.0 technologies can increase labor productivity by 15-30%¹ in manufacturing environments . This productivity boost is largely due to the enhanced connectivity between factory workers and machines, facilitated by connected worker platforms and smart factory workforce solutions. These platforms allow workers to access critical information, receive real-time updates, and communicate with team members instantly, all of which contribute to a more efficient and responsive manufacturing process.

The Power of Industrial IoT in Manufacturing

Industrial IoT (IIoT) is a game-changer for connected factory workers, providing them with real-time data and actionable insights to enhance productivity and streamline processes. By integrating IIoT-enabled tools, workers can predict potential machine failures, optimize workflows, and ensure seamless collaboration with automated systems.

A case study from Bosch highlights the tangible benefits of IIoT implementation: predictive maintenance reduced downtime by up to 45% and increased equipment availability by 30%. These improvements allow connected factory workers to shift from reactive problem-solving to proactive decision-making, enhancing both productivity and job satisfaction.

Moreover, the same case study reported that IIoT solutions contributed to operational cost savings of up to 25% while improving safety through automated monitoring systems. For connected factory workers, this means fewer unexpected disruptions, a safer work environment, and more time to focus on high-value tasks that drive overall factory performance.

Wearable Technology: Enhancing Safety and Efficiency

Wearable technology in manufacturing is becoming increasingly popular as companies look for ways to enhance worker safety and efficiency. These devices, which range from smart glasses to wearable sensors, provide factory workers with real-time information and alerts, enabling them to perform tasks more accurately and safely

For example, smart glasses equipped with augmented reality (AR) can overlay digital instructions onto the physical environment, guiding workers through complex assembly processes with greater precision. Additionally, wearable sensors can monitor worker vitals and environmental conditions, providing real-time alerts if a worker is in danger, thus improving connected worker safety.

LightGuide reported AR reduced mistakes by 30%, while an MIT study found machine learning cut errors by 25%³

By integrating wearables into daily workflows, manufacturers equip their teams with smarter, safer tools to excel in modern production environments.

Real-Time Data: The Heartbeat of Smart Manufacturing

Real-time data is the lifeblood of the connected factory worker’s operations. By providing immediate access to performance metrics, predictive maintenance insights, and production data, workers can prevent downtime and enhance efficiency.

Cisco reports that real-time data can reduce unplanned downtime by nearly 50% and shorten product introduction cycles by over 23%⁴. For connected workers, this access means they can respond to challenges instantly, improving workflows and ensuring consistent production quality.

By putting actionable information directly into workers’ hands, manufacturers equip their teams with the tools to succeed in high-pressure, fast-paced environments.

Connected Worker Platforms: Bridging the Digital Divide

Connected worker platforms combine mobile solutions, communication tools, and analytics into one cohesive interface, simplifying tasks for factory workers. Workers can track inventory, communicate with supervisors, and manage machine performance from a single platform.

These platforms don’t just improve efficiency—they empower workers by giving them more control over their tasks and insights into their work environment. By fostering collaboration between workers and automation systems, connected worker platforms create a harmonious relationship between humans and technology.

The Human Element: Engaging and Empowering Workers

While technology plays a crucial role, the connected factory worker thrives when they feel engaged and valued. Tools that provide real-time feedback and performance insights encourage workers to take ownership of their roles, fostering motivation and loyalty.

Manufacturers who prioritize the human element see better results in productivity and quality. The connected worker is more than just a cog in the machine—they’re a vital part of a collaborative and innovative manufacturing ecosystem.

The Future of the Connected Factory Worker

As manufacturing continues to evolve, the connected factory worker will play an increasingly pivotal role. Tools like augmented reality, wearable technology, and IIoT are enabling workers to handle complex tasks with greater precision and adapt to dynamic production needs.

Solutions like Yelhow’s Alex exemplify how connected worker platforms enhance productivity, streamline workflows, and improve safety. By integrating advanced technologies, these solutions prepare workers for the future of manufacturing while addressing current operational challenges.

The connected factory worker isn’t just adapting to new tools—they’re redefining what it means to work in manufacturing. Their role is central to creating efficient, safe, and sustainable production environments for the future.

References

1 – “Industry 4.0: Reimagining manufacturing operations after COVID-19” (Article by McKinsey & Company, 2020).

2 – “Industrial IoT: how companies increase transparency and optimize operational efficiency”, (White Paper by Bosch, 2021).

3 – “AI In Enhancing Human-Machine Interaction In Manufacturing”, (Article by Tarun Singh published on IOSR Journal of Mechanical and Civil Engineering, 2024).

4 – “Becoming a Smarter Manufacturer”, (Report by Pierfrancesco Manenti published by SCM World, 2015).