An industrial training plan should be more than a list of courses, it must protect output while keeping people safe. The right approach maps roles to skills, forecasts qualification gaps, and designs cross-training that fits production. With real-time tracking, credible validation, and quick backfill, you keep shift readiness high even when key operators are absent.

What a Training Plan Looks Like on a Production Line

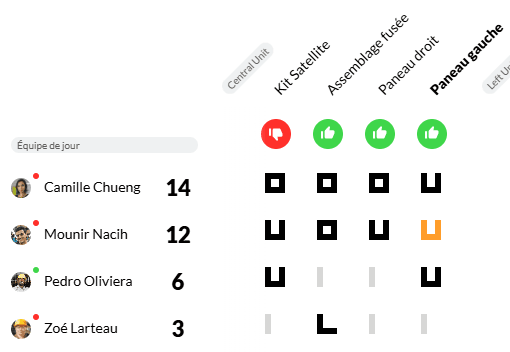

Old plans focus on events completed. Effective plans focus on capability available at the station. That means knowing who can run which asset, at what proficiency, and under which work instruction version. Link people to skills, then link skills to machines, materials, and variants. Now you can see qualified availability, not just headcount.

Map Roles to Skills for Shift Readiness

Start with the stations and quality gates that protect throughput. List the skills needed for each one, including changeovers and inspections. Define levels such as Awareness, Assisted, Independent, and Trainer. Add validity windows, because recency matters. Connect operators to these skills and record evidence. This skills view gives supervisors a fast way to confirm coverage before the shift starts.

Make the view usable:

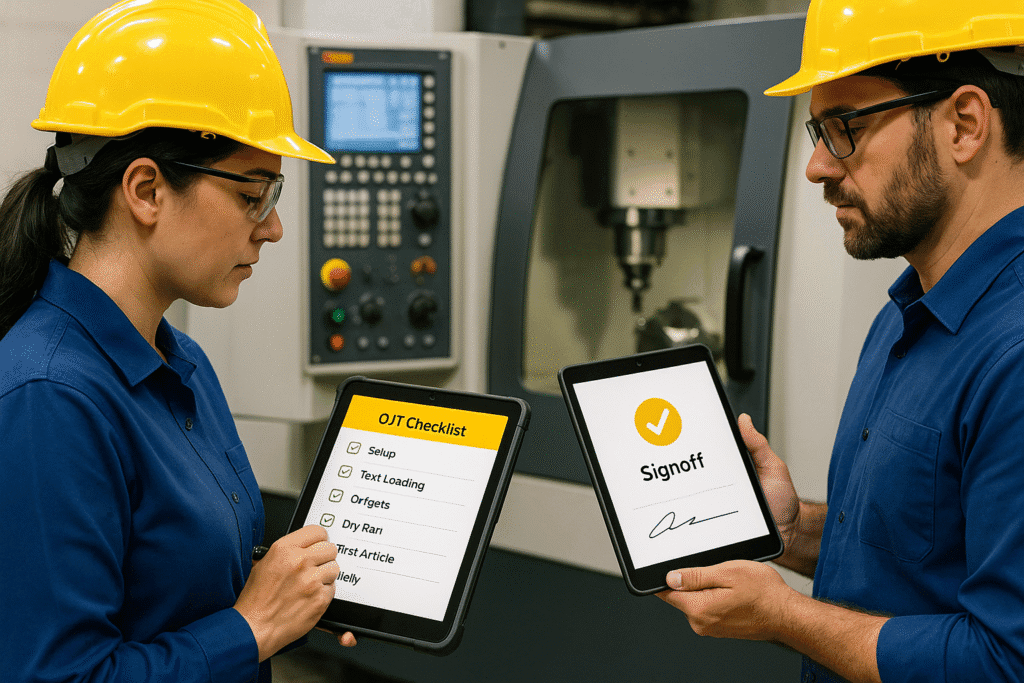

- Break tasks into clear, auditable elements.

- Tie each task to a machine or process family.

- Attach signoffs, OJT checklists, and short quizzes as proof.

Forecast Qualification Gaps to Protect OEE

Overall equipment effectiveness (OEE) suffers when a station sits idle for lack of a qualified person. Forecast coverage by looking four to twelve weeks ahead. Combine demand plans, vacation calendars, and expirations. You will see where coverage drops below safe levels. Build cross-training plans to remove those bottlenecks before they slow the line.

Practical forecasting moves:

- Model common absence patterns by shift.

- Flag thin coverage for safety-critical steps.

- Align trainer capacity with onboarding waves.

- Surface upcoming expirations for roles that guard first-pass yield (FPY).

Build Blended Learning That Respects Takt Time

Training should speed up the work, not interrupt it. Use short modules for theory and repeatable practice at the machine for skill. Place most theory off shift. Use natural pauses for quick practice. Group assessments near real tasks to confirm transfer.

Design the path:

- Microlearning for fundamentals on mobile devices.

- Structured OJT with checklists and visual aids.

- Shadowing and simulations for rare events like first article inspection.

- Quizzes for key rules and safety points.

- Coach and verify at set milestones, such as 20, 50, and 80 percent independence.

Track in Real Time and Validate Competence

Supervisors need confidence that a person is qualified for a task today. Keep records tied to the current work instruction. Capture who did what, when it was checked, and by whom. Use consistent assessment formats. Schedule refreshers based on risk level or defect trends. Provide dashboards that show completions, overdue items, and shift coverage at a glance.

Operational essentials:

- Version control for SOPs and work instructions.

- Electronic signoffs with role-based permissions.

- Practical demos and observations in addition to quizzes.

- Auto reminders for requalification.

Coverage Planning for Absences and Short-Notice Changes

Absences happen. Line stoppages do not have to follow. With a live picture of skills and recency, supervisors can fill a gap in minutes and understand the ripple effects across the line.

Plan for resilience:

- Maintain two qualified backups for every critical station on each shift.

- Create a small pool of multi-skilled operators who can rotate where needed.

- Keep playbooks for common issues like a weld cell down or a packaging surge.

- Measure time to backfill and work to bring it down.

A quick scenario: Thirty minutes before the night shift, a filler operator reports sick. A supervisor checks the skills view, finds two people with current signoffs, and redeploys one. The line starts on time and meets plan.

Metrics That Matter to the Line

Measure results that affect output and stability. Use these to manage the program and show progress.

- Time to independence by role and line.

- Skill coverage per shift, with a target of two backups for each critical station.

- Backfill response time from gap detection to redeployment.

- FPY trend after training events.

- Unplanned downtime linked to staffing or qualification.

Avoid celebrating completions without performance impact. Watch recency and on-the-job evidence. Short, focused interventions usually beat long classroom sessions.

A 30-60-90 Plan to Put This in Motion

Days 1 to 30: Baseline and quick wins

Build a skills inventory for two pilot lines. Define task lists and levels. Import must-have records. Stand up OJT checklists and signoff flows. Set requalification cadences for safety and quality steps.

Days 31 to 60: Blend and integrate

Create blended paths for the roles that guard throughput. Launch microlearning and trainer standards. Start a twelve-week coverage forecast. Connect training records to document control so signoffs always point to the right version.

Days 61 to 90: Scale and automate

Extend cross-training to remove the top three bottlenecks. Enforce minimum backup rules per station. Give supervisors a dashboard for coverage and expirations. Review KPIs each week and tune curricula based on OEE and FPY shifts.

By day ninety, you should see faster onboarding, steadier coverage, and fewer scramble moments before shifts.

Training Plan Outcomes for Manufacturing Managers: Coverage, Throughput, Less Downtime

This is what a good plan delivers for your team and your targets:

- Shift starts on time because coverage is clear and current.

- Changeovers move faster because people practice the steps that matter.

- Absences cause redeployment, not idle stations.

- Supervisors spend less time chasing records and more time coaching.

- Quality issues trigger targeted refreshers, not broad training days.

Pointer KPIs: Time to independence, coverage per shift with two backups, backfill time under fifteen minutes, FPY improvement after specific modules.

FAQ for the Shop Floor

Put theory off shift. Use microlearning before the day starts. Practice at the machine during natural pauses. Keep each step short and focused.

One trainer to one or two learners works well for risky tasks. Use one to three for simpler steps and when you have clear checklists.

Tag modules to the changeover tasks they address. Compare changeover time before and after. Validate with supervisor observations and run charts.

How Alex Puts Your Training Plan to Work

Alex turns these ideas into daily results.

View who is qualified by station and shift. See proficiency levels and recency. Plan cross-training to keep two backups for critical roles.

Tie signoffs to the right SOP version. Capture electronic confirmations. Keep clear history of assessments and requalifications.

Project coverage weeks or months ahead. Get alerts for expirations. Surface certified replacements in minutes when someone is absent.

Deliver short modules, OJT checklists, and quizzes. Standardize trainer signoff flows. Cut time to independence without missing takt time.

Link to your quality system and document control so procedure changes trigger requalification. Align with scheduling and HR data to plan trainers and cohorts.

Track coverage per shift, backfill time, time to independence, and FPY shifts so improvements are visible and defensible.

Learn how Alex boosts shop-floor teams