Leveraging Mobile Technology on the Factory Floor to Create Durability

In modern manufacturing, mobile technology is crucial for enhancing communication and operational efficiency. By integrating mobile devices, workers can access information, report issues, and communicate from anywhere on the factory floor, facilitating real-time data sharing among workers, supervisors, and management.

This innovation brings managers closer to on-the-ground operations, leading to more agile and responsive manufacturing processes that boost productivity and efficiency.

Key Benefits of Mobile Technology on the Factory Floor

Mobile devices enable immediate communication among team members, allowing for quick information sharing and timely feedback. Workers can use messaging apps, video calls, and collaborative platforms to stay connected, coordinate tasks, and ensure alignment with production goals and timelines. This real-time communication minimizes delays and enhances overall collaboration.

One of the most significant advantages of mobile technology is the ability to access real-time information from anywhere on the factory floor. Workers can retrieve data on production schedules, inventory levels, and equipment status, enabling them to make informed decisions quickly. This accessibility reduces the need for physical documentation and manual data entry, thereby decreasing the likelihood of errors and enhancing overall accuracy.

Mobile devices streamline the process of reporting and resolving issues. Workers can quickly capture and document problems using mobile apps, complete with photos and detailed descriptions. This information can be instantly shared with maintenance teams or supervisors, facilitating faster diagnosis and repair. The ability to report issues in real-time helps minimize downtime and maintain smooth production flow.

Mobile technology acts as a gateway for implementing other digital tools and applications. For instance, mobile devices can integrate with enterprise resource planning (ERP) systems, manufacturing execution systems (MES), and quality management systems (QMS). This integration allows for seamless data exchange and synchronization across different platforms, enhancing overall operational efficiency.

The portability of mobile devices provides workers with greater flexibility and mobility. They can move freely around the facility while staying connected to essential information and communication channels. This mobility is particularly beneficial for tasks that require frequent movement, such as inspections, quality control, and equipment maintenance.

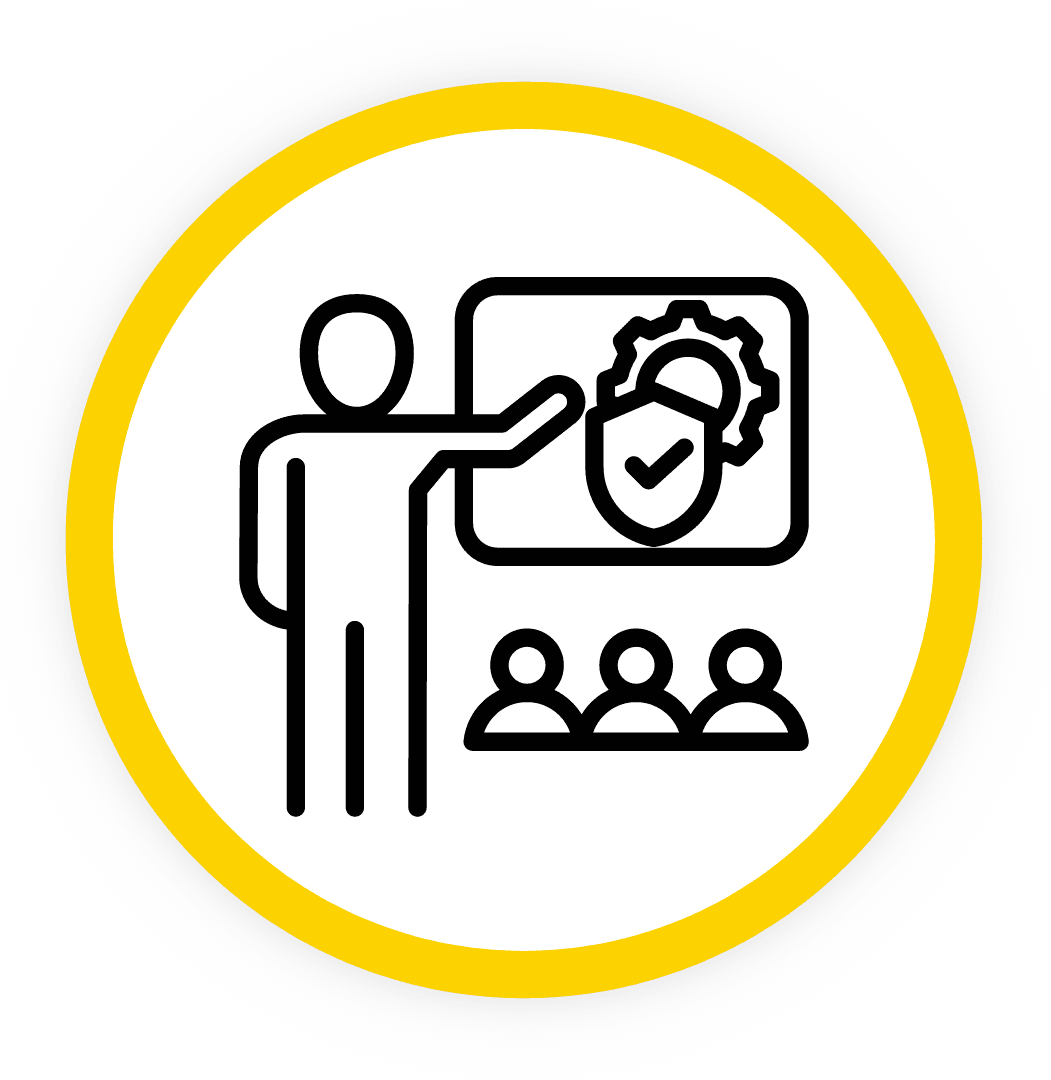

Digital collaboration for a connected manufacturing workforce

Article by McKinsey

Implementing a mobile-based maintenance system, a leading automotive manufacturer targets a 20-30% productivity boost and reduced downtime, aligning with McKinsey’s $100 billion digital collaboration potential.

A leading automotive manufacturer embraced a mobile-based maintenance management system to revolutionize its operations. By equipping technicians with tablets, the company enabled instant access to critical resources like equipment manuals, maintenance schedules, and diagnostic tools, leading to faster, more accurate maintenance and significantly reducing downtime.

McKinsey’s analysis highlights the broader impact of such digital collaboration, projecting that it could unlock over $100 billion in value across industries and boost productivity by 20-30%. This shift reflects a strategic move towards digital solutions to meet the challenges of modern manufacturing.

You can check the full article here.

Best Practices for Implementing Mobile Technology

Ensure Device Reliability and Connectivity

Choosing durable, compatible mobile devices and ensuring strong connectivity are key to a successful rollout. Opt for rugged industrial tablets and smartphones, and ensure a reliable Wi-Fi or LTE/5G network to support seamless communication and data transfer throughout the facility.

Provide Thorough Training

Offer detailed training on mobile devices and applications, including operation, troubleshooting, and data security best practices. Properly trained employees will be more confident and efficient, maximizing the benefits of the technology.

Track and Improve

Performance

Choosing durable, compatible mobile devices and ensuring strong connectivity are key to a successful rollout. Opt for rugged industrial tablets and smartphones, and ensure a reliable Wi-Fi or LTE/5G network to support seamless communication and data transfer throughout the facility.

Enhance Data Security

Enhanced connectivity requires robust data security. Implement encryption, secure access controls, and regular software updates to protect sensitive information and prevent unauthorized access.

Conclusion

Leveraging mobile technology on the factory floor provides significant advantages, enhancing both communication and operational efficiency. Tools like Alex enable real-time information access, streamline communication across all levels of the organization, and support the seamless integration of other digital systems. By making critical information readily accessible across roles, Alex fosters improved productivity, reduces downtime, and cultivates a more agile, responsive workforce.

As the manufacturing industry evolves, adopting advanced communication strategies is essential to staying competitive and achieving operational excellence. Embracing mobile technology is not just a passing trend but a strategic imperative for building a more connected, efficient, and productive future.

Innovation, digital tools, user testimonials…

to not miss anything of the industry of the future, subscribe to our newsletter